Optimized Insulation for Data Center Transformers

Industry Trends

The global data center transformer market is projected to grow significantly during the next five years, driven by the growing demand for Artificial Intelligence (AI), cloud computing, big data analytics, and internet services. Increasing digitalization across multiple industries, rising use of AI, and general internet use have led to huge data processing and storage needs that require a more robust and efficient power infrastructure.

There is increasing demand for energy-efficient transformers with an emphasis on reducing energy consumption and minimizing carbon footprint. Transformers are designed to ensure consistent and stable power distribution, which is critical to maintaining operational efficiency, reducing downtime, and meeting high-energy demands.

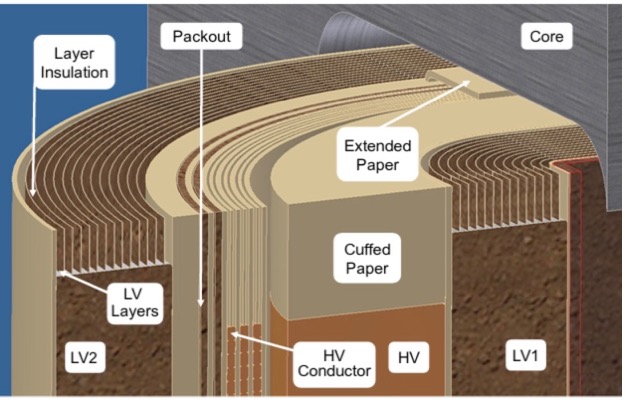

Transformers for data centers have become increasingly larger (2500 kVA and above). Commonly, these transformers are designed with layer-type windings up to 6300 kVA and even greater.

Challenges for Data Center Transformers

Design Challenges:

Data center applications can lead to increased thermal, electrical, and mechanical stresses on transformers

OEM/End-User Challenges:

- Under-utilized excessive transformer capacity

- Shorter life span/reliability due to high-stress environments

Optimized Insulation System

Transformer solid insulation largely defines the major transformer characteristics, including:

- Size, weight, footprint, and cost

- Losses and efficiency

- Long-term reliability and failure resistance

As layer insulation is the key solid insulation material, a special “engineered paper” with enhanced properties can optimize and improve performance for the following reasons:

- Withstands higher temperatures

- Enables faster and higher-quality processing at the OEM factory

- Has improved dielectric performance

- Can help to reduce the overall size and weight of the transformer

- Aids cost efficiencies and can yield a general reduction in the cost of the transformer

Layer-Type Transformer Windings – Key Solid Insulation Material = Paper

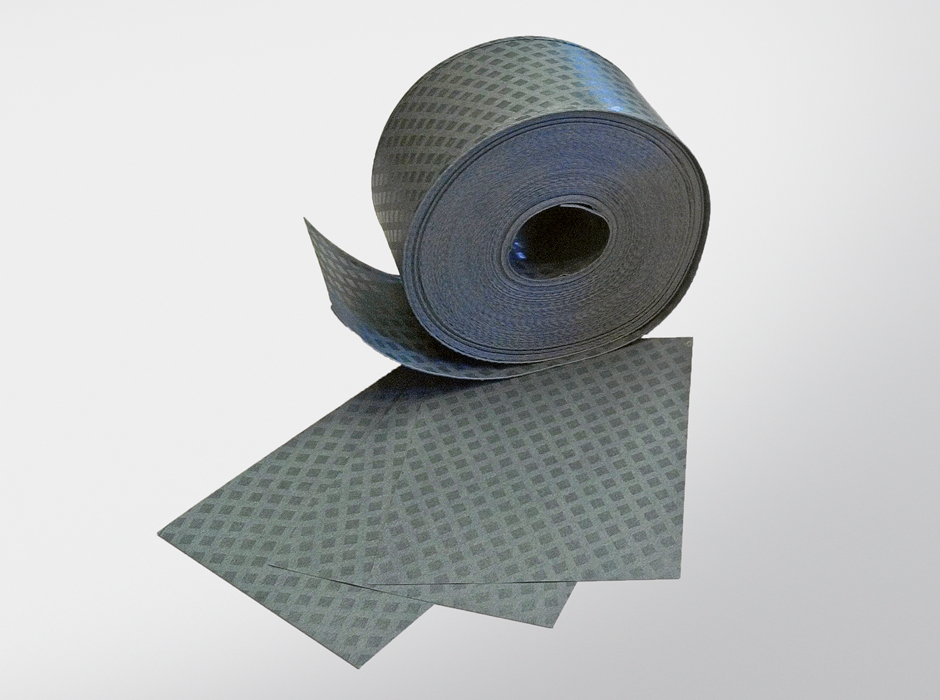

Advanced Insulation Paper – Diamond Pattern Enhanced (DPE) Paper from Weidmann

DPE is a special-grade layer insulation paper for liquid-immersed layer-type transformers. INSULutions™ DPE provides:

- Higher thermal endurance (in both mineral oil and ester liquid) – slower aging

- Better (faster) drying – quality and productivity improvement

- Better (faster) impregnation with dielectric liquids – quality and productivity improvement

- Better dielectric performance – potentially improved dielectric insulation design

DPE – Higher Thermal Class Paper for Slower Aging and Longer Life

INSULutions™ DPE is qualified up to 130°C in mineral oil and up to 140°C in ester liquid. Weidmann’s IEEE C57.100 – 2011-certified aging tests helped to determine the end-of-life criteria of transformer insulating systems and a procedure to define the insulation system life equation and thermal index, which then relates to the thermal class of the insulation system.

INSULutions™ DPE Diamond Pattern Enhanced (DPE) layer insulation paper

Application Options to Utilize the Benefit of Higher Thermal Class DPE Paper

1. High-Temperature-Rated Designs

Using Weidmann’s enhanced insulating DPE paper in layer-type transformers allows:

- Increase up to 75°C Average Winding Rise (AWR) temperature with mineral oil

- Increase up to 85°C AWR temperature in ester liquid

Insulation system thermal class options using DPE paper (IEEE terminology)

2. Longer Life in Operation

- An additional 10°C temperature “safety margin”

- Provides more than two times longer insulation life

- Increases transformer resilience against increased ambient and/or operational temperatures

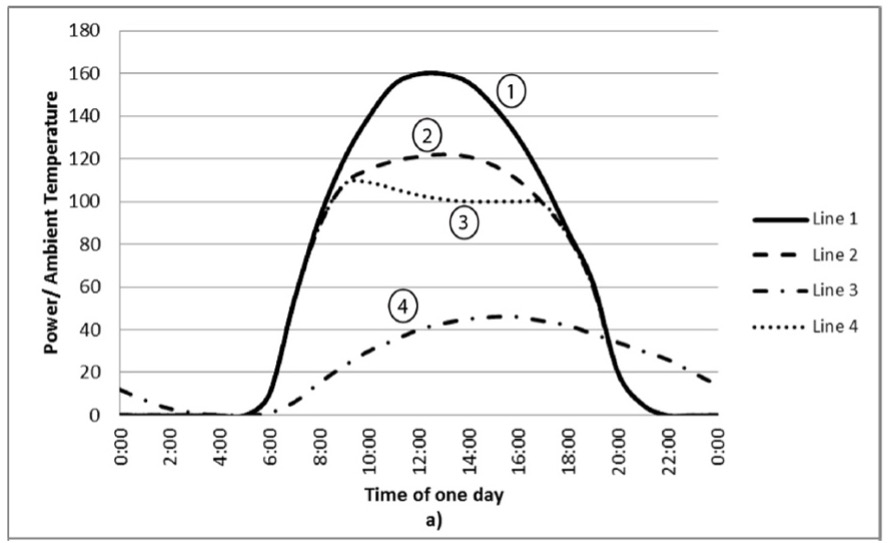

3. Higher Overload Capability

- Option 1: Same size transformer with about 20% higher overload capability

- Option 2: Smaller transformer in size, weight, and cost with equivalent overload capability and no load losses

The diagram shows an example of a 100 kVA inverter-connected transformer (3), with “Initial Load” = 30% of nameplate power and “Peak Load” duration = 8 hours

4. Dual Temperature Nameplate Designs and Sustainable Peak Load Transformers

- Enhanced DPE allows new dual temperature nameplate transformers: in mineral oil – 65°C/ 75°C AWR; in ester liquids – 65°C/ 85°C AWR or 75°C/ 85°C AWR

- Transformers can be continuously loaded at peak load kVA with no effect on transformer reliability or lifetime

- Great also for variable loads when transformers operate below nameplate rating for significant periods

Summary

Data center transformers are subject to variable loads, inverter connection harmonics, and potentially high ambient temperatures, which lead to increased thermal, electrical, and mechanical stresses on transformers.

Data center transformers, which are typically high-voltage, layer-type transformers, demand a reliable, cost-efficient solid insulation solution. DPE paper’s faster dry-out rate, faster impregnation, and enhanced dielectric performance contribute to improved quality and reliability, reduced Factory Acceptance Test (FAT) failure rate, and increased transformer resilience in operation.

In addition, DPE’s higher thermal class and enhanced dielectric performance allow:

- Optimized insulation system design

- High-temperature-rated designs

- Longer life in operation

- Higher overload capability

- Dual-temperature nameplate designs

- Sustainable peak load transformers

In conclusion, to ensure adequate, uninterrupted power from data center transformers, the solid insulation should be optimized for resilience and long-lasting performance. Incorporating a special “engineered paper” such as DPE paper from Weidmann as the key solid insulation material offers enhanced properties that provide new opportunities for transformer optimization and reliability.